Preventive Mechanical Maintenance

Scheduled inspections and preventive care for your building's critical mechanical systems. Boilers, chillers, cooling towers, pumps, make-up air units, and building automation—maintained on a predictable schedule with documentation that satisfies boards, auditors, and insurers.

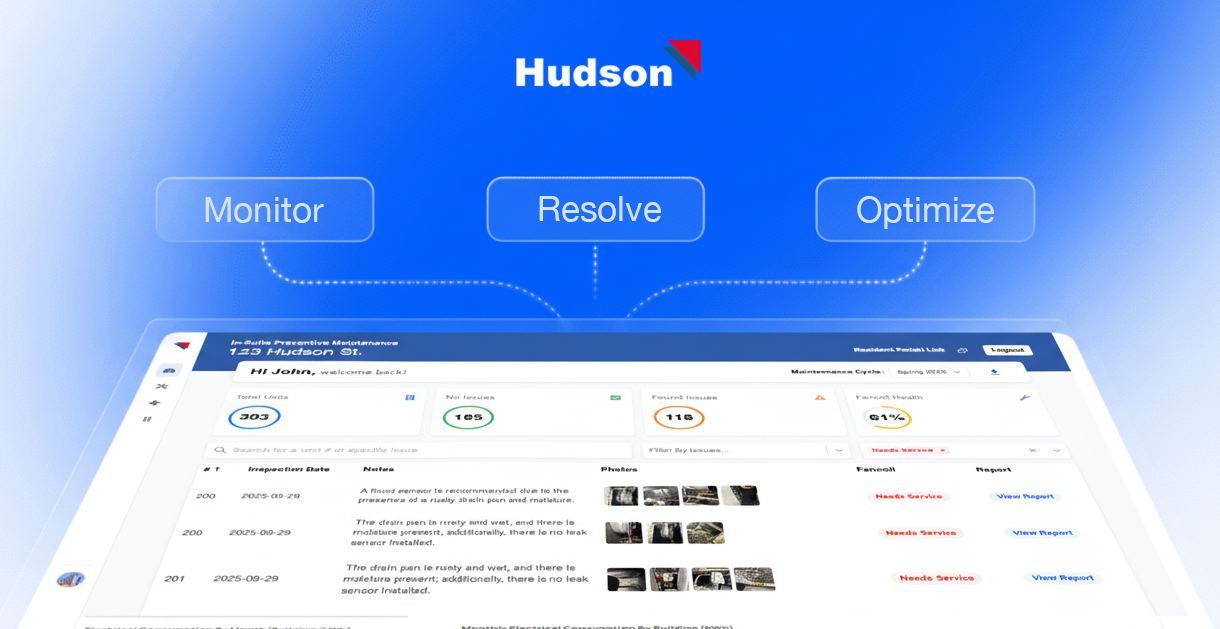

Our preventive maintenance programs are engineered to extend equipment life, reduce emergency calls, and keep your building's mechanical infrastructure operating at peak efficiency. Every visit is logged in our Smart Mechanical Dashboard with photos, readings, and AI-driven health scores.

Request Program Proposal

Predictable scheduling

Monthly, quarterly, or seasonal visit cadences aligned with your building's operational calendar and changeover periods.

Compliance documentation

Service records, inspection reports, and equipment histories ready for audits, insurance renewals, and reserve fund studies.

AI-driven insights

Our Smart Mechanical Dashboard tracks equipment health scores, flags trending issues, and recommends proactive repairs before failures occur.

The business case for preventive maintenance

For property managers and boards, preventive maintenance isn't just about avoiding breakdowns—it's about financial predictability, liability reduction, and protecting the building's long-term asset value.

Financial benefits

- Reduced emergency repair costs: Preventive programs catch wear items before they fail catastrophically—a $300 pump seal replacement versus a $15,000 flooded mechanical room.

- Extended equipment life: Properly maintained boilers, chillers, and cooling towers routinely exceed design life by 5-10 years, deferring major capital expenditures.

- Energy savings: Clean heat exchangers, calibrated controls, and optimized setpoints reduce utility costs by 10-25% compared to neglected systems.

- Insurance benefits: Documented maintenance history can reduce premiums and strengthens claims positions if incidents occur.

- Reserve fund planning: Detailed equipment condition reports support accurate lifecycle forecasting for status certificates and reserve fund studies.

Operational benefits

- Fewer resident complaints: Consistent heating, cooling, and hot water means fewer calls to management and happier occupants.

- Regulatory compliance: TSSA boiler inspections, refrigerant tracking, Legionella protocols, and fire safety requirements—all documented and current.

- Reduced board liability: Demonstrable due diligence in maintaining life-safety and building systems protects directors and officers.

- Vendor accountability: Photo-documented visits, signed service reports, and portal access ensure transparency and accountability.

- Simplified transitions: Comprehensive equipment histories ease property manager transitions and support due diligence for building sales.

Equipment covered under preventive programs

Our preventive maintenance programs cover all major mechanical systems found in Toronto condominium buildings. Equipment is grouped by system type with manufacturer-recommended service intervals and industry best practices.

Heating Systems

- Gas-fired boilers (atmospheric & condensing)

- Electric boilers

- Steam boilers & converters

- Heat exchangers

- Expansion tanks

- Boiler feed systems

Cooling Systems

- Centrifugal & screw chillers

- Air-cooled chillers

- Cooling towers & fluid coolers

- Condenser water treatment

- Chilled water systems

- Free cooling economizers

Air Handling

- Make-up air units (MUAs)

- Rooftop units (RTUs)

- Energy recovery ventilators

- Exhaust fans & systems

- Garage ventilation

- Corridor pressurization

Pumping Systems

- Heating circulator pumps

- Chilled water pumps

- Condenser water pumps

- Domestic booster pumps

- Sump & sewage ejectors

- Fire pumps (inspection support)

Controls & Automation

- Building automation systems (BAS)

- DDC controllers & sensors

- VFD drives & motor starters

- Pneumatic controls (legacy)

- Energy metering systems

- Alarm monitoring interfaces

Specialty Equipment

- Pool dehumidifiers & heaters

- Domestic hot water systems

- Generator transfer switches

- Heat recovery systems

- Water treatment systems

- Glycol systems

Specialized maintenance add-ons

Extend your preventive program with specialized maintenance for critical building systems. Each add-on includes dedicated inspection schedules, compliance documentation, and integration with your Smart Mechanical Dashboard.

Generator Maintenance

Keep your emergency backup power ready when you need it most. Our generator maintenance program ensures reliable operation during outages and satisfies insurance requirements.

- Monthly no-load run tests with load bank testing annually

- Fuel system inspection and fuel polishing

- Battery testing and replacement tracking

- Coolant and oil analysis

- Transfer switch testing and exercising

- TSSA compliance coordination

- 24/7 emergency generator dispatch

Chiller Maintenance

Protect your building's most expensive mechanical asset. Chillers require specialized care to maintain efficiency and prevent catastrophic compressor failures.

- Refrigerant charge verification and leak detection

- Compressor oil analysis and acid testing

- Condenser and evaporator tube inspection

- Eddy current testing (tube integrity)

- Control sequence optimization

- Vibration analysis and trending

- Federal refrigerant logging compliance

Cooling Tower

Ensure safe, efficient heat rejection while managing Legionella risk. Cooling towers require vigilant maintenance and water management programs.

- Basin cleaning and fill media inspection

- Fan motor and belt service

- Drift eliminator inspection

- Water treatment program oversight

- Legionella sampling coordination

- Winterization and summer startup

- Public health compliance documentation

Bundle add-ons with your preventive program

Buildings that bundle specialized maintenance with base preventive programs receive priority scheduling, consolidated reporting, and simplified invoicing. One contract, one vendor, complete mechanical coverage.

Sample preventive maintenance tasks

Every piece of equipment has specific manufacturer-recommended service intervals. Below are examples of tasks performed during preventive visits—actual scope depends on your building's equipment mix and chosen service tier.

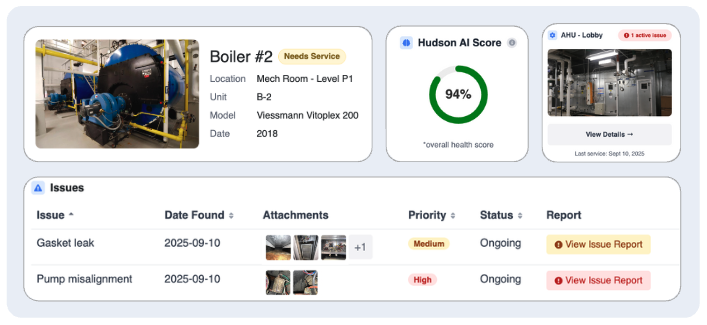

Boiler preventive tasks

- Combustion analysis and burner tuning

- Heat exchanger inspection and cleaning

- Safety control testing (high limit, low water cutoff, flame safeguard)

- Flue and venting inspection

- Gasket and seal inspection

- Expansion tank pressure check

- Water chemistry sampling coordination

Chiller preventive tasks

- Refrigerant charge and leak check

- Compressor oil analysis

- Condenser and evaporator tube inspection

- Starter and contactor inspection

- Control sequence verification

- Vibration and sound level baseline

- Refrigerant log documentation

Cooling tower preventive tasks

- Basin cleaning and debris removal

- Fill media inspection

- Fan motor and belt inspection

- Float valve and makeup water check

- Drift eliminator inspection

- Water treatment coordination

- Legionella sampling coordination

- Winterization and summer startup

Pump preventive tasks

- Bearing lubrication and temperature check

- Seal and packing inspection

- Coupling alignment verification

- Vibration measurement

- Motor amp draw and voltage check

- Strainer cleaning

- Isolation valve operation

Air handling preventive tasks

- Filter replacement (per schedule)

- Belt inspection and tensioning

- Coil cleaning and inspection

- Damper operation and actuator check

- Drain pan and condensate line clearing

- Economizer calibration

- Outdoor air measurement

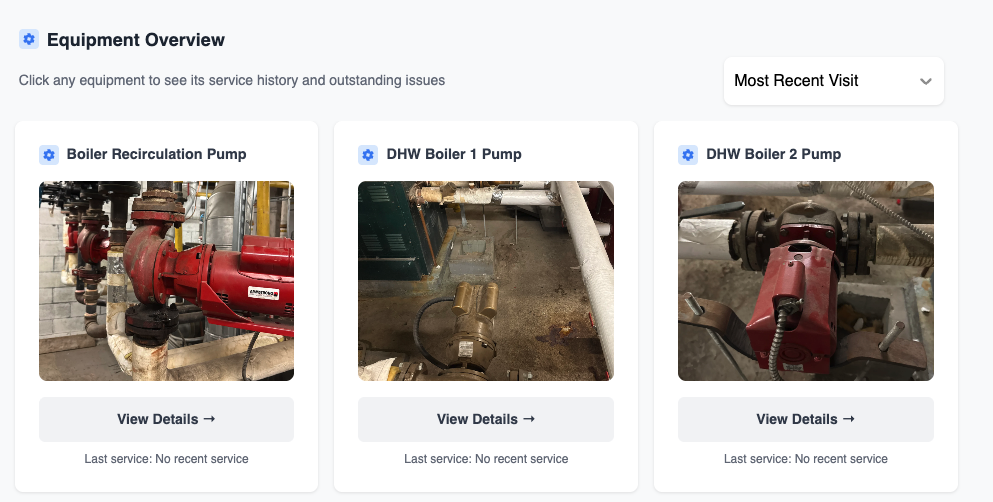

Smart Mechanical Dashboard

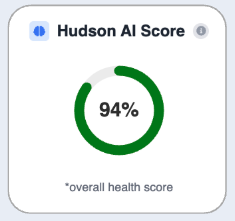

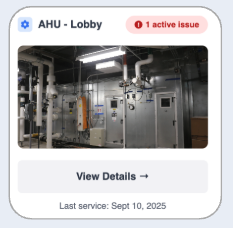

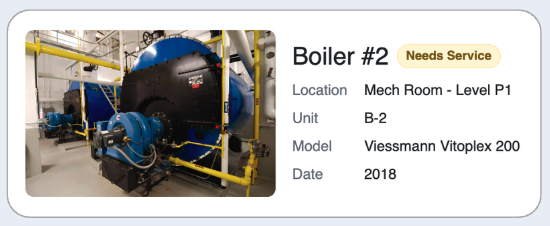

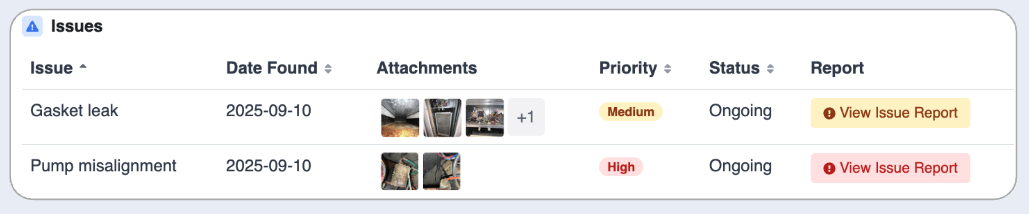

Every preventive maintenance program includes access to Hudson's proprietary Smart Mechanical Dashboard—a centralized platform where property managers and boards can view equipment status, service history, and AI-generated health scores.

- Equipment inventory: Complete asset list with make, model, serial, and warranty status.

- Service history: Every visit logged with photos, readings, and technician notes.

- AI health scores: Algorithms flag equipment trending toward failure.

- Issue tracking: Open items, recommended repairs, and capital planning items.

- Document library: Manuals, warranties, and compliance certificates.

- Board reports: One-click summaries for AGMs and board meetings.

Regulatory compliance support

Toronto condominiums face a complex web of regulatory requirements for mechanical systems. Our preventive programs include documentation and coordination support for key compliance areas.

TSSA boiler compliance

We coordinate with TSSA inspectors, ensure equipment is ready for annual inspections, and maintain records of certificates of inspection (CIs) and operating permits in your dashboard.

Refrigerant tracking

Federal regulations require tracking of refrigerant additions and disposals for systems over 10 kg. We maintain compliant logs and report unusually high consumption that may indicate leaks.

Legionella risk management

Cooling towers require documented water management programs. We coordinate sampling schedules, review treatment reports, and ensure your building meets public health guidelines.

Fire & life safety

Mechanical systems interface with fire suppression, smoke control, and emergency power. We verify proper operation and coordination with your fire safety contractor.

For property managers & boards

We understand that mechanical maintenance decisions ultimately rest with the board and require clear justification. Our programs are designed to give property managers the tools they need to demonstrate due diligence and boards the confidence that their building is protected.

- Transparent pricing: Fixed annual contracts with clear scope—no surprise invoices.

- Board presentations: We can attend AGMs or board meetings to present equipment status and recommendations.

- Capital planning support: Detailed equipment condition assessments to inform reserve fund studies.

- Transition support: Comprehensive handover documentation when property managers change.

Related services

- Comprehensive mechanical maintenance for full-service coverage including repairs

- Generator maintenance for emergency power systems

- Chiller maintenance for specialized cooling system care

- Cooling tower maintenance for heat rejection systems

- Capital projects for equipment replacements and upgrades

FAQs

Ready to discuss a preventive program?

Request a proposal or schedule a complimentary building assessment. We'll review your equipment, discuss your building's needs, and provide a customized program recommendation with transparent pricing.

Request Proposal