Blower Motor Repair for Toronto Condos

No airflow from your vents? Fan squealing or humming? Motor not starting? Your fan coil or heat pump blower motor likely needs repair or replacement.

The blower motor is the heart of your HVAC airflow. When it fails, you get no heating or cooling—even if the rest of the system works fine. Hudson HVAC diagnoses and replaces failed blower motors, capacitors, and blower assemblies in all types of condo HVAC equipment across Toronto.

Could be a failed motor, bad capacitor, or electrical issue. We diagnose quickly and get your air moving again.

Restore Your Airflow

Blower motor issues leave you with no heating or cooling. We diagnose quickly—sometimes it's a simple capacitor, other times the motor needs replacement. We stock common motors and can often complete repairs the same day.

Signs your blower motor needs service

These symptoms indicate a failing or failed blower motor. Sometimes it's a simple capacitor fix; other times motor replacement is needed.

No Airflow

No air coming from vents when system is on. Motor has failed completely—most common symptom.

Squealing Sound

High-pitched squealing when motor runs. Worn bearings—motor will fail soon.

Humming/No Start

Motor hums but doesn't spin. Usually a failed capacitor—cheaper fix than motor.

Weak Airflow

Fan runs but airflow is weak. Could be dirty blower wheel, failing motor, or clogged filter.

Intermittent Operation

Fan works sometimes, not others. Motor overheating and shutting down—replacement needed.

Burning Smell

Electrical burning smell from unit. Motor windings overheating—turn off immediately.

What causes blower motor failure in Toronto condos?

Blower motors work hard, running thousands of hours per year. Here's why they fail and how to extend their life.

Age & Bearing Wear

Motor bearings wear over time, causing friction and heat. After 10-15 years of heavy use, bearings fail—often preceded by squealing sounds. This is normal end-of-life.

Airflow Restriction

Clogged filters, blocked returns, or dirty blower wheels make the motor work harder. This causes overheating and premature failure. Regular filter changes are the best prevention.

Capacitor Failure

The run capacitor helps the motor start and run efficiently. A failed capacitor causes the motor to hum without starting, or run weakly. Capacitors are inexpensive and often the first thing to check.

Overheating

Motors that run too hot due to dust buildup, restricted airflow, or electrical issues will eventually burn out. Intermittent operation (works, then shuts off) often indicates thermal overload.

Dust Accumulation

Heavy dust buildup on the motor and blower wheel creates imbalance and strain. Routine cleaning during maintenance visits helps prevent this type of accelerated wear.

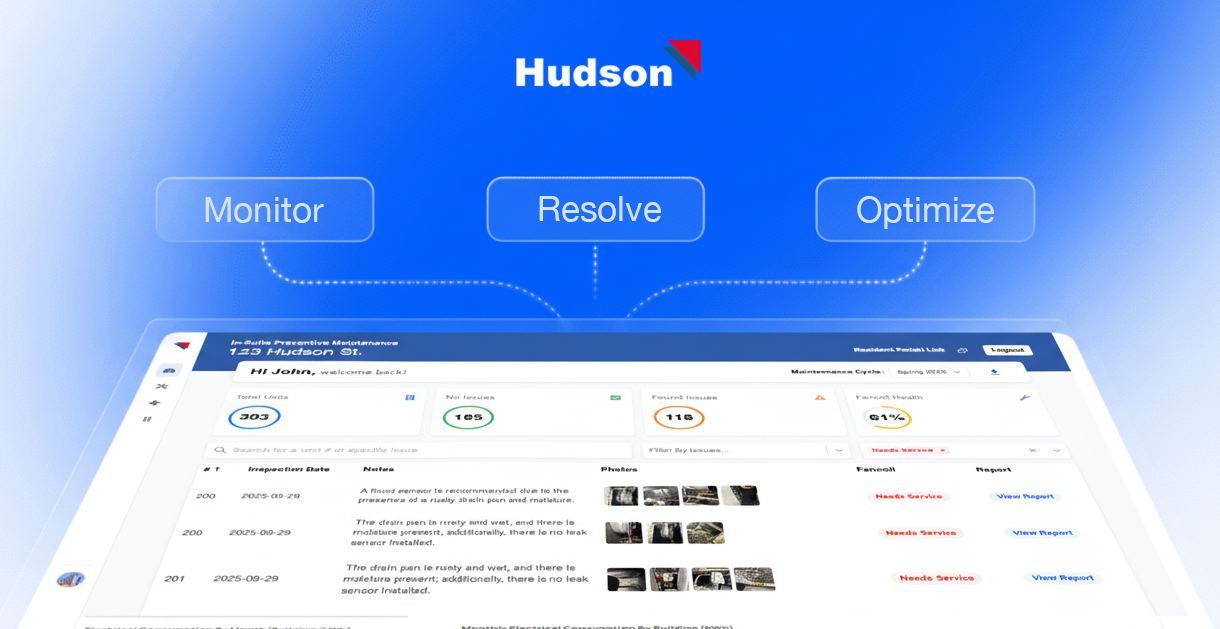

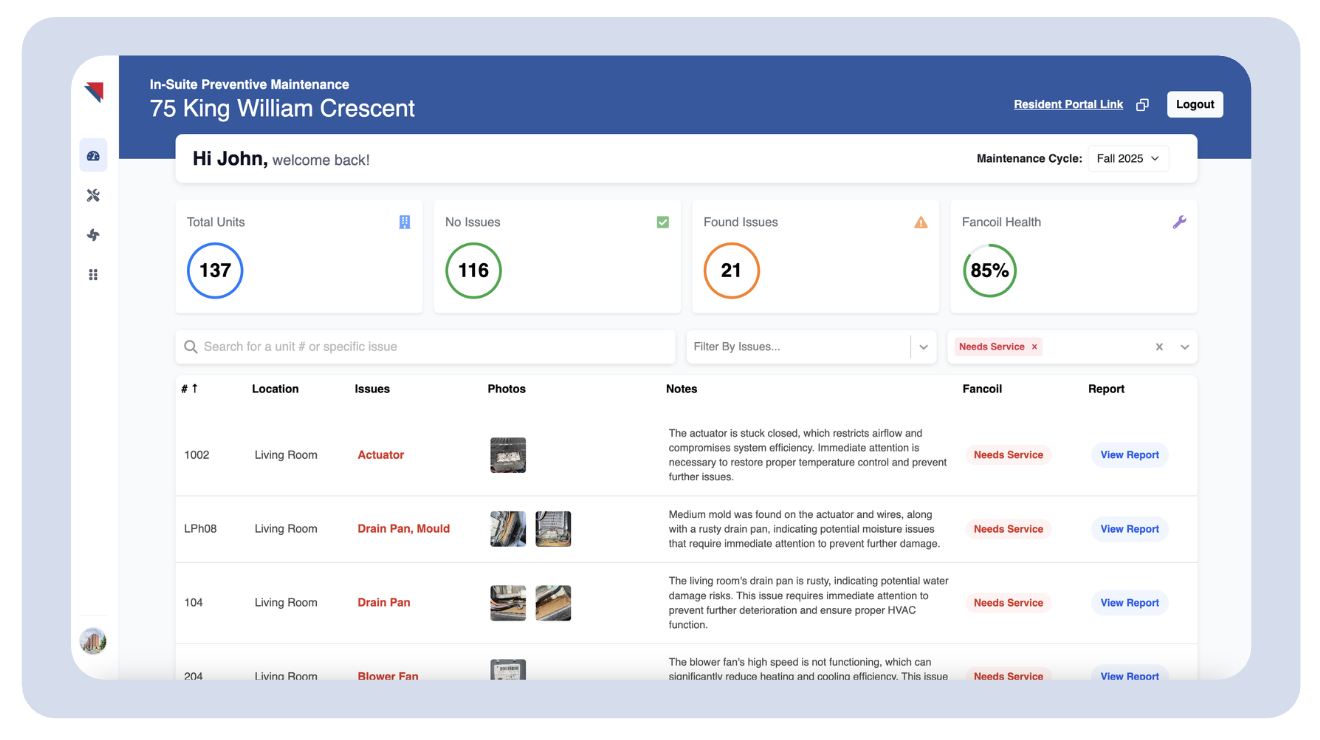

Our blower motor repair process

A thorough diagnostic process to identify the issue and restore your airflow. Here's what to expect.

Electrical Diagnosis

We check power supply, capacitor, control board, and wiring. Often the issue is a simple capacitor replacement rather than the motor itself.

Motor Assessment

We test the motor for continuity, shorts, and mechanical operation. Seized bearings, burned windings, or damaged shafts mean replacement is needed.

Part Identification

We identify the motor type (PSC/ECM), horsepower, and mounting style. Common motors are stocked; specialty motors are sourced within 1-2 days.

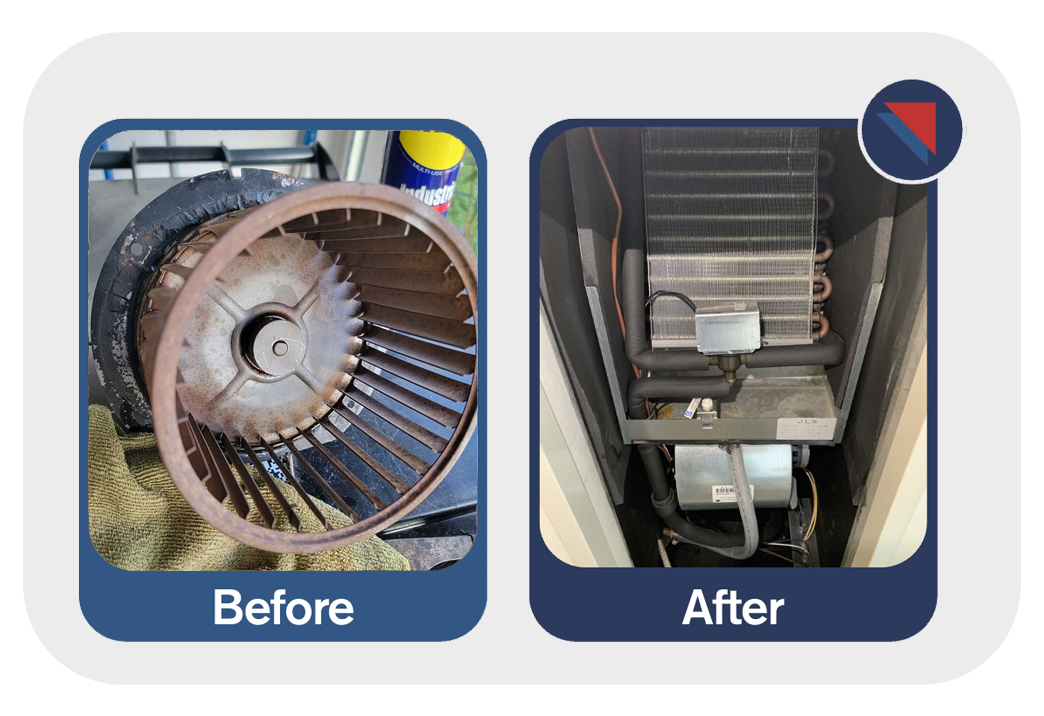

Motor & Wheel Service

We remove the blower assembly, swap the motor (and clean or replace the blower wheel if needed), reassemble, and secure all connections.

Airflow Testing

We run the system, verify proper airflow from all vents, check motor amperage, and ensure quiet, balanced operation.

Documentation

You receive a service report with motor specifications, work performed, and warranty information. We note any recommendations for prevention.

Motor types we replace

We service and replace blower motors from all major manufacturers found in Toronto condo fan coils and heat pumps.

Motor Types

- PSC motors – Permanent Split Capacitor, fixed speed, most common

- ECM motors – Electronically Commutated, variable speed, efficient

- Shaded pole motors – Small motors in compact units

- Direct drive motors – Motor shaft directly attached to wheel

- Belt drive motors – Separate motor with belt to blower

Related Components

- Run capacitors – Start and run capacitors for PSC motors

- Blower wheels – Squirrel cage fans attached to motor

- Motor mounts – Rubber isolators and mounting brackets

- Wiring harnesses – Motor connections and plugs

- Control boards – ECM motor controllers

Common Motor Brands

- Genteq/GE – ECM and PSC motors

- Emerson/US Motors – Commercial and condo units

- Fasco – OEM and replacement motors

- AO Smith/Century – Standard replacements

- OEM specific – Carrier, Trane, etc.

Replacement Options

- Direct replacement – Same specs as original motor

- Universal motors – Multi-speed replacements

- ECM upgrade – Replace PSC with efficient ECM

- Capacitor only – When motor is still good

- Complete assembly – Motor + wheel + housing

Equipment we service motors for

Blower motors are found in all types of condo HVAC equipment. We replace motors for all systems found in Toronto condominiums.

Fan Coils

2-pipe & 4-pipe systems

Heat Pumps

Water-source WSHP

ERVs/HRVs

Energy recovery units

PTACs

Through-wall units

Why Toronto condo residents choose Hudson for blower motor repair

Condo HVAC specialists

We focus exclusively on condo HVAC systems. Our technicians know fan coil and heat pump motors inside and out—all brands, all types.

Common motors stocked

We stock common blower motors and capacitors on our service vehicles. Many repairs can be completed on the first visit.

Thorough diagnosis

We check capacitors, wiring, and controls first. Sometimes a $30 capacitor fixes the issue—we don't replace motors unnecessarily.

Upfront pricing

You know the cost before we start. We explain the difference between repair options and help you make an informed decision.

Fast turnaround

Most motor repairs are completed the same day when we have parts. No days without airflow—we restore comfort quickly.

Quality parts

New motors come with manufacturer warranty. Our labor is also guaranteed. You're covered if anything goes wrong.

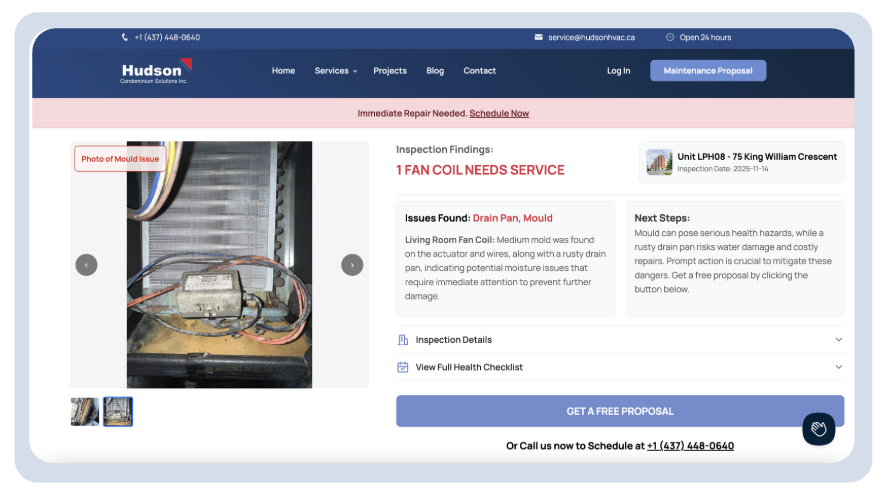

For property managers

Blower motor failures mean residents with no airflow—a critical comfort issue. We help you resolve these quickly with minimal callbacks.

- Fast response: No airflow is a priority issue. We schedule quickly to minimize resident complaints.

- Common motors stocked: We carry popular motor sizes, enabling same-visit repairs for many units.

- Honest diagnosis: We check capacitors and simple fixes first—no unnecessary motor replacements.

- Clear documentation: Service reports detail motor specs, work performed, and any building-wide patterns.

Related services & resources

Related repair services

Frequently asked questions

No airflow? Fan not running? Get your comfort back.

Schedule blower motor diagnosis and repair. We'll identify the issue and restore proper airflow to your condo.