Chiller Retrofit: Upgrade Your Building's Cooling

Chillers are the most expensive equipment in any building's mechanical system. When replacement time comes, the decisions you make will impact your building's comfort, energy costs, and reserve fund for decades.

We manage complete chiller retrofit projects from equipment selection through commissioning. Our experience with centrifugal, screw, scroll, and modular chillers means we can recommend the right solution for your building's specific needs and budget.

Request Project Quote View Recent ProjectsEnergy efficiency gains

Modern chillers are 20-40% more efficient than equipment from the 1990s-2000s. The energy savings often pay back a significant portion of replacement costs over the equipment's life.

Refrigerant compliance

Many older chillers use refrigerants being phased out under federal regulations. New equipment uses modern refrigerants with better environmental profiles and assured long-term availability.

Improved reliability

New chillers with modern controls integrate seamlessly with building automation, offer remote monitoring capabilities, and eliminate the surprise failures that plague aging equipment.

Why proactive chiller replacement?

Chillers don't fail gracefully. A catastrophic compressor failure in July leaves your building without cooling during the hottest days—and emergency replacements cost 30-50% more than planned projects.

- Avoid emergency costs: Planned replacement allows competitive bidding, proper equipment selection, and scheduling that minimizes impact on residents.

- Energy cost reduction: Modern chillers reduce electricity consumption significantly—savings of $20,000-50,000+ annually are common for mid-rise condos.

- Reserve fund planning: Proactive replacement aligns with reserve fund studies and can be timed to match available funding.

- Utility rebates: Energy-efficient chiller upgrades often qualify for utility incentive programs, reducing net project costs.

Our retrofit process

Chiller replacement is a major capital project requiring careful planning and execution. Our process ensures successful outcomes with minimal disruption to building operations.

Assessment

- Existing equipment evaluation

- Building load analysis

- Mechanical room assessment

- Rigging path evaluation

- Electrical capacity review

Engineering

- Equipment selection

- Piping design

- Electrical engineering

- Controls integration plan

- Permit applications

Procurement

- Equipment ordering

- Lead time management

- Utility rebate applications

- Staging coordination

- Rigging arrangements

Demolition

- Refrigerant recovery

- Oil removal

- Equipment disconnection

- Old chiller removal

- Area preparation

Installation

- Rigging and placement

- Piping connections

- Electrical hookup

- Controls wiring

- Refrigerant charging

Commissioning

- System startup

- Performance verification

- BAS integration

- Operator training

- Documentation package

Chiller manufacturers we install

We work with all major chiller manufacturers and can recommend the best fit for your building's needs, budget, and long-term maintenance considerations.

Smardt

Oil-free centrifugal

Trane

Centrifugal & screw

Carrier

All chiller types

York

Centrifugal & screw

Daikin

Air & water-cooled

McQuay

Centrifugal & screw

Multistack

Modular chillers

Dunham-Bush

Screw & scroll

Compliance & safety

Chiller replacement involves significant regulatory requirements. We handle all compliance aspects so you can focus on building operations.

TSSA Compliance

All work performed by TSSA-certified refrigeration technicians. Proper permits, inspections, and documentation maintained throughout the project.

Refrigerant Handling

Certified recovery of existing refrigerant with proper documentation. New equipment charged with modern, compliant refrigerants. Full federal logging compliance.

Health & Safety

Full OHSA compliance including rigging safety, confined space protocols, and hazardous material handling. WSIB coverage for all workers on site.

For property managers & boards

Chiller replacement is one of the largest capital expenditures a condo corporation faces—often $300,000-$800,000+. We understand the governance, financial planning, and communication requirements for projects of this scale.

- Board presentations: We attend board meetings to present options, explain trade-offs, and answer technical questions in plain language.

- Reserve fund alignment: Projects can be timed to match reserve fund availability, and we provide documentation supporting reserve fund study updates.

- Utility rebates: We identify and apply for applicable utility incentive programs, maximizing rebate recovery to offset project costs.

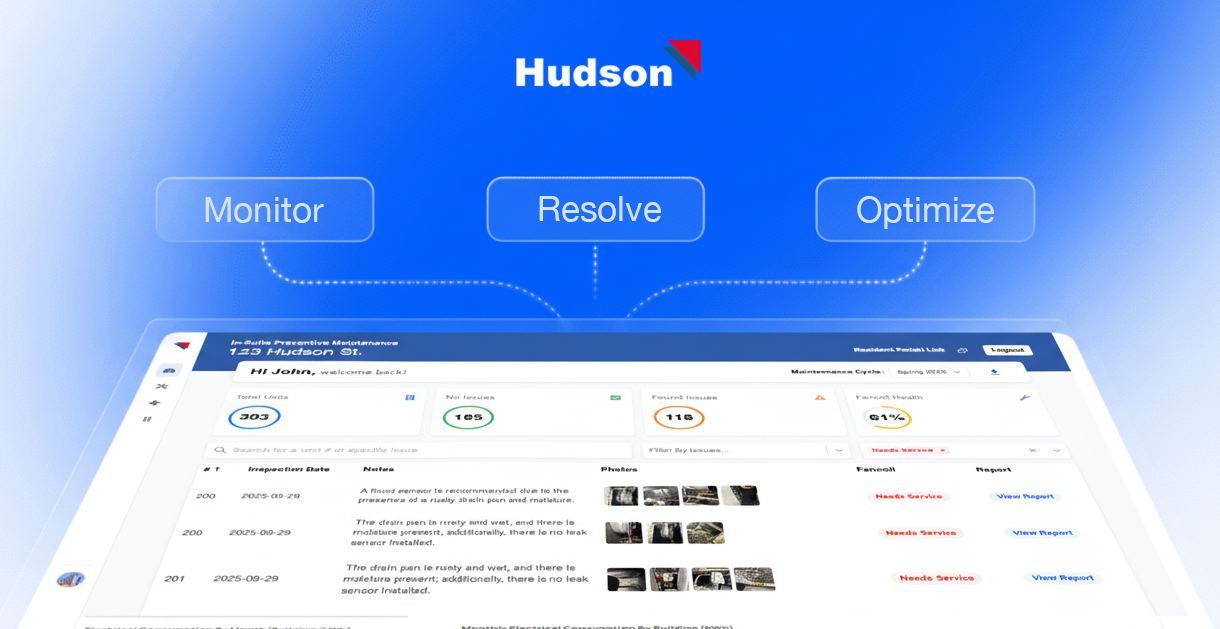

- Progress reporting: Regular updates through our dashboard keep boards informed of project status, milestones, and any issues requiring attention.

Chiller Projects Across Toronto

We've completed chiller retrofit projects in buildings across the GTA—from single-chiller mid-rises to multi-chiller high-rise plants. See our project portfolio for examples of our work.

Related project solutions

- Chiller maintenance to extend equipment life and optimize performance

- Fan coil retrofit for in-suite equipment replacement

- Heat pump replacement for water-source heat pump upgrades

- Riser replacement for piping infrastructure upgrades

- Recent projects to see our completed work

FAQs

Ready to plan your chiller retrofit?

Request a site assessment and detailed proposal. We'll help you understand your options, timeline, and budget requirements for a successful project.