Condo Heat Pump Replacement Project

Whether you're a condo owner replacing your suite's heat pump or a property manager coordinating a building-wide replacement program, we handle projects of every scale with the same professional approach.

We've completed hundreds of heat pump replacements across Toronto condos—from single suite upgrades to full building retrofits. Ask about our bundle discounts when you add a smart thermostat or maintenance plan to your installation.

Request Project Quote View Recent ProjectsProfessional project management

Dedicated project managers coordinate scheduling, resident communication, and quality control. You get regular updates and a single point of contact.

TSSA certified installations

All work performed by licensed technicians following TSSA regulations. Proper refrigerant handling, permits, and documentation for your building's records.

On-time delivery

We commit to schedules and meet them. Our logistics ensure equipment arrives when needed and crews stay on track throughout the project.

For condo owners & residents

If your heat pump is failing, running inefficiently, or no longer keeping your suite comfortable, you don't have to wait for a building-wide program. We replace individual suite heat pumps with the same quality and professionalism we bring to large projects.

- Individual suite replacement: Book your heat pump replacement directly. We'll assess your unit, recommend the right equipment for your building's water loop, and complete the installation—typically in one day.

- Multi-zone discounts: Larger suites with multiple heat pumps? Get discounted pricing when replacing 2 or more units in the same suite.

- Same-day quotes: Contact us with your unit details and we'll provide pricing quickly—no waiting for building-wide assessments.

- Flexible scheduling: We work around your schedule, with weekend and evening appointments available for individual replacements.

Discounts & Bundle Offers

Save more when you bundle services or replace multiple units:

Why building-wide replacement?

Many Toronto condos built in the 1990s-2000s are now facing aging heat pump infrastructure. Reactive replacement—waiting for units to fail—creates ongoing disruption, inconsistent equipment, and higher per-unit costs.

- Cost savings: Building-wide programs reduce per-unit cost by 15-25% compared to individual replacements through volume pricing and efficient scheduling.

- Improved efficiency: Modern heat pumps are significantly more efficient. Building-wide upgrades can reduce suite energy consumption by 20-30%.

- Consistent equipment: Same model throughout the building simplifies maintenance, parts inventory, and troubleshooting for years to come.

- Refrigerant compliance: Newer units use modern refrigerants. Building-wide replacement eliminates legacy refrigerant issues and future phase-out concerns.

Our replacement process

From initial assessment to project closeout, we manage every detail to ensure a successful replacement with minimal disruption to residents and building operations.

Assessment

- Site survey and unit inspection

- Equipment condition report

- Water loop compatibility

- Electrical capacity review

- Scope definition

Proposal

- Equipment selection

- Detailed pricing

- Project timeline

- Payment schedule options

- Board presentation support

Planning

- Equipment procurement

- Permit applications

- Scheduling coordination

- Resident notification

- Staging area setup

Installation

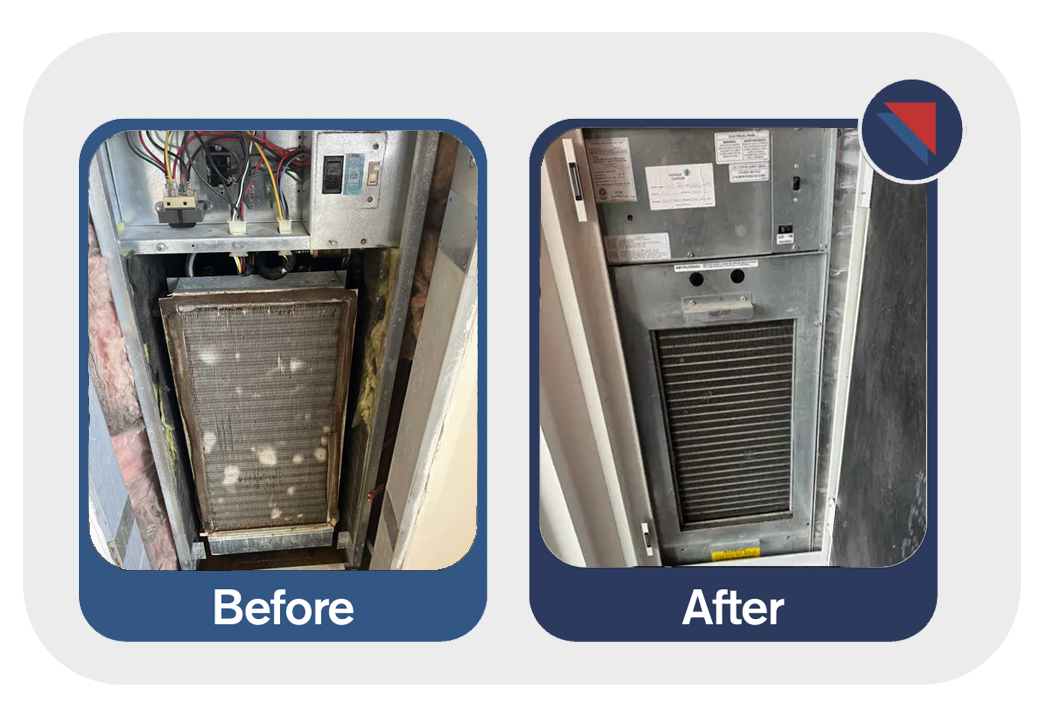

- Refrigerant recovery

- Old unit removal

- New unit installation

- Water loop connections

- Electrical hookup

Commissioning

- Refrigerant charging

- Heating & cooling test

- Thermostat calibration

- Leak inspection

- Performance verification

Closeout

- Final inspection

- Documentation package

- Warranty registration

- Resident orientation

- Dashboard setup

Heat pump manufacturers we install

We work with leading water-source heat pump manufacturers to match the right equipment to your building's water loop system, space constraints, and budget requirements.

Johnson Controls

Commercial grade

ClimateMaster

Water source specialist

Carrier

Industry leader

Trane

Premium quality

Omega

Canadian made

Whalen

Condo specialist

McQuay

Daikin brand

First Co.

Value engineering

Compliance & safety

Every installation meets or exceeds regulatory requirements. We handle permits, inspections, and documentation so you have complete records for your building files.

TSSA Compliance

All work performed by TSSA-licensed technicians. Proper permits obtained, inspections scheduled, and certificates filed. Your building stays compliant with Ontario regulations.

Refrigerant Handling

Certified technicians recover, reclaim, and document all refrigerant per federal regulations. Complete tracking from recovery through disposal or reuse.

Health & Safety

Full compliance with OHSA requirements. Site-specific safety plans, PPE protocols, and safe work procedures. We carry comprehensive liability and WSIB coverage.

For property managers & boards

Major capital projects require board approval, resident communication, and careful financial planning. We support you through every stage of the decision-making and execution process.

- Board presentations: We attend board meetings to present proposals, answer questions, and address concerns directly.

- Reserve fund alignment: Projects can be phased across fiscal years to match reserve fund cash flow.

- Resident communication: We provide template notices and coordinate scheduling to minimize complaints.

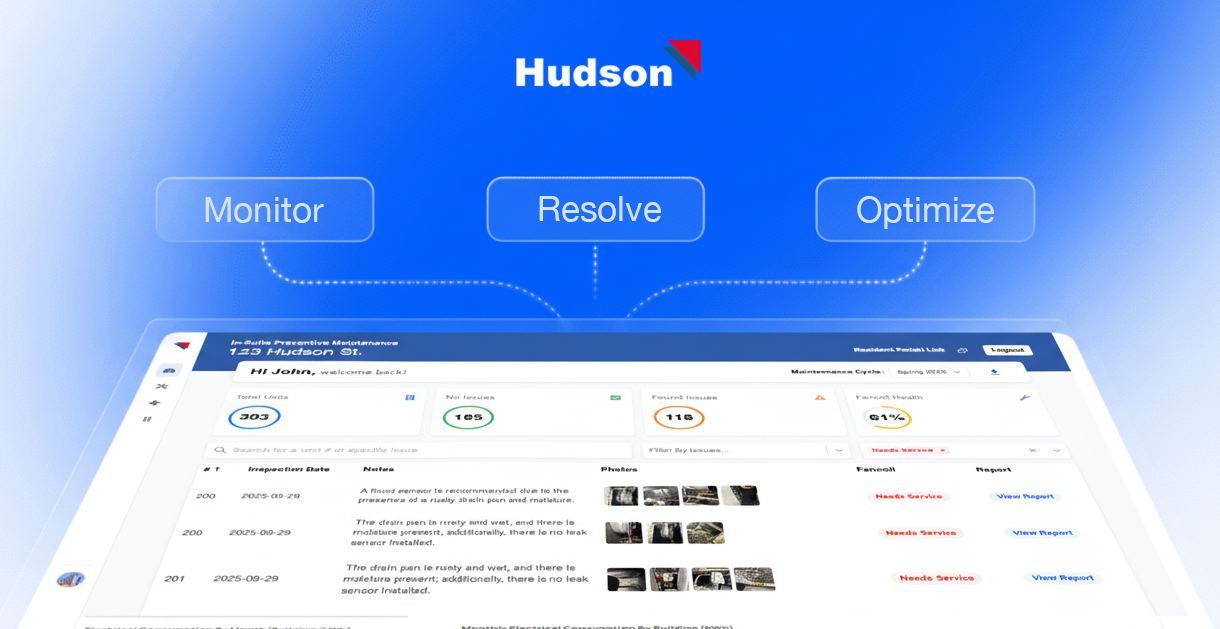

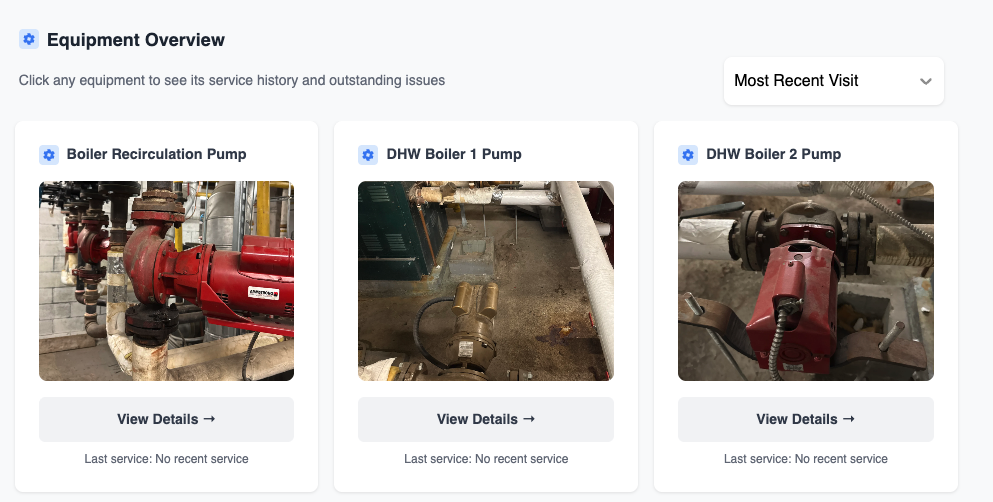

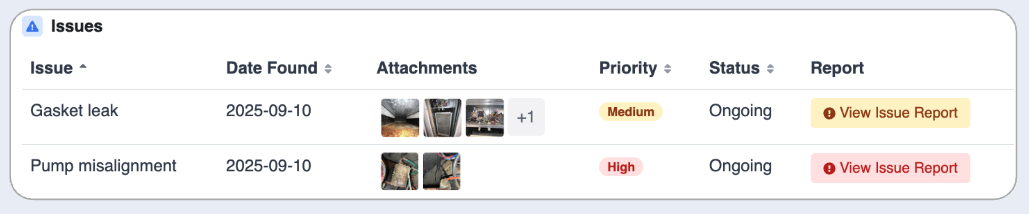

- Progress reporting: Regular updates through our dashboard showing completed units, schedule status, and any issues.

- Warranty management: All equipment registered with manufacturers. Warranty documentation in your dashboard for future reference.

Building-Wide Heat Pump Projects Completed

We've completed numerous building-wide heat pump replacement projects across Toronto—delivered on time and on budget. See our recent work in our portfolio.

Related project solutions

- Fan coil retrofit for fan coil replacements

- Heat pump maintenance for ongoing preventive care

- Preventive mechanical maintenance for complete building coverage

- Recent projects to see our completed work

FAQs

Ready to replace your heat pump?

Whether you need a single unit replaced or you're planning a building-wide program, we're here to help. Contact us for a quote—individual residents and property managers welcome.