VFD Installation: Smart Energy Savings

Variable Frequency Drives are one of the highest-ROI energy upgrades available for condo mechanical systems. By matching motor speed to actual demand, VFDs typically reduce pump and fan energy consumption by 30-70%.

We design and install VFD systems for pumps, fans, and cooling towers throughout your mechanical room. Our projects include proper electrical infrastructure, controls integration, and commissioning to ensure you capture the full energy savings potential.

Request Project Quote View Recent ProjectsDramatic energy savings

The cube law means small speed reductions yield huge energy savings. Running a pump at 80% speed uses only 50% of the energy. Typical savings are 30-70% on affected equipment.

Extended equipment life

Soft starts eliminate the mechanical stress of across-the-line starting. Reduced speed operation decreases bearing wear, seal stress, and vibration—extending motor and pump life significantly.

Better system control

VFDs enable precise flow and pressure control. Maintain constant differential pressure, optimize cooling tower approach, and match system capacity to actual building loads automatically.

VFD applications in condo buildings

VFDs deliver the greatest savings on equipment with variable loads. Here are the most common and effective applications in condominium mechanical systems.

Condenser Water Pumps

Highest savings potential. Match flow to actual chiller load instead of running full speed 24/7. Typical savings: 40-60%.

Cooling Tower Fans

Control approach temperature precisely. Eliminate on/off cycling that wastes energy and stresses motors.

Chilled Water Pumps

Maintain constant differential pressure across the building. Reduce flow when cooling demand is low.

Heating Water Pumps

Variable flow based on heating demand. Greatest savings during shoulder seasons with partial loads.

MAU Supply Fans

Adjust fresh air volume based on occupancy or CO2 levels. Reduce airflow during low-demand periods.

Garage Exhaust Fans

CO-based demand ventilation instead of constant operation. Major savings in underground parking garages.

The cube law: why VFDs work

Energy consumption for pumps and fans follows the affinity laws—specifically, power varies with the cube of speed. This physics creates enormous savings potential.

- 90% speed = 73% power: A small 10% speed reduction cuts energy use by 27%.

- 80% speed = 51% power: Running at 80% uses only half the energy of full speed.

- 70% speed = 34% power: At 70% speed, energy consumption drops to just one-third.

- 50% speed = 12.5% power: Half speed uses only 1/8 the energy—a 87.5% reduction.

Most HVAC systems are designed for peak load but operate at partial load most of the time. VFDs capture these savings automatically by matching speed to actual demand.

Our installation process

VFD installation requires careful planning to ensure proper sizing, electrical infrastructure, and controls integration for maximum savings.

Assessment

- Motor nameplate data collection

- Operating profile analysis

- Electrical infrastructure review

- Savings calculation

- Rebate eligibility check

Engineering

- VFD sizing and selection

- Electrical design

- Controls sequence development

- BAS integration plan

- Permit applications

Procurement

- VFD ordering

- Electrical materials

- Enclosure and mounting

- Rebate pre-approval

- Scheduling coordination

Electrical

- Disconnect installation

- VFD mounting

- Power wiring

- Motor wiring

- Grounding and shielding

Controls

- BAS integration

- Sensor installation

- Control wiring

- Sequence programming

- Alarm setup

Commissioning

- VFD parameter setup

- Motor tuning

- Control loop tuning

- Performance verification

- Operator training

VFD manufacturers we install

We work with leading VFD manufacturers and select equipment based on application requirements, BAS compatibility, and long-term reliability.

ABB

Industry standard

Danfoss

HVAC specialists

Yaskawa

Premium drives

Schneider

Altivar series

Siemens

Building integration

Eaton

PowerXL series

Allen-Bradley

PowerFlex series

Toshiba

HVAC optimized

Compliance & technical considerations

VFD installations involve electrical work and controls integration requiring proper planning and execution.

Electrical Code

All work by licensed electricians per Ontario Electrical Safety Code. Proper permits, ESA inspection, and documentation. Panel capacity verified before installation.

Harmonic Mitigation

VFDs can generate harmonics that affect power quality. We specify line reactors, DC chokes, or active filters as needed to meet IEEE 519 recommendations.

BAS Integration

Proper integration with building automation enables remote monitoring, trending, and optimization. We configure communication protocols and verify data exchange.

For property managers & boards

VFD installations offer one of the best returns on investment for building energy upgrades. The math is compelling—significant savings with relatively modest capital investment.

- Strong ROI: Typical payback periods of 2-5 years, often reduced to 1-3 years with utility rebates. After payback, savings flow directly to the operating budget.

- Utility rebates: Most utility incentive programs offer significant rebates for VFD installations. We identify and apply for all applicable programs.

- Reserve fund friendly: VFD projects can often be funded from operating budgets due to quick payback, avoiding reserve fund impact.

- Measurable results: Energy savings are easily verified through utility bills. We provide before/after analysis to demonstrate ROI.

VFD Projects Across Toronto

We've completed VFD installations in buildings across the GTA—from single-pump retrofits to complete mechanical room modernizations. See our project portfolio for examples.

Related project solutions

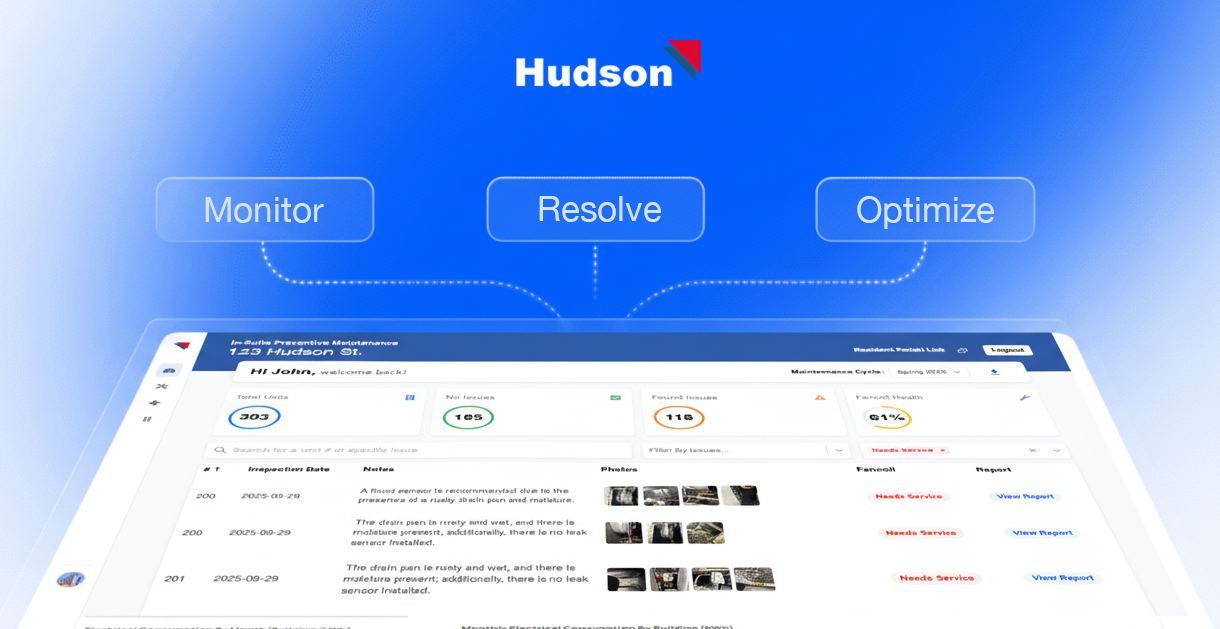

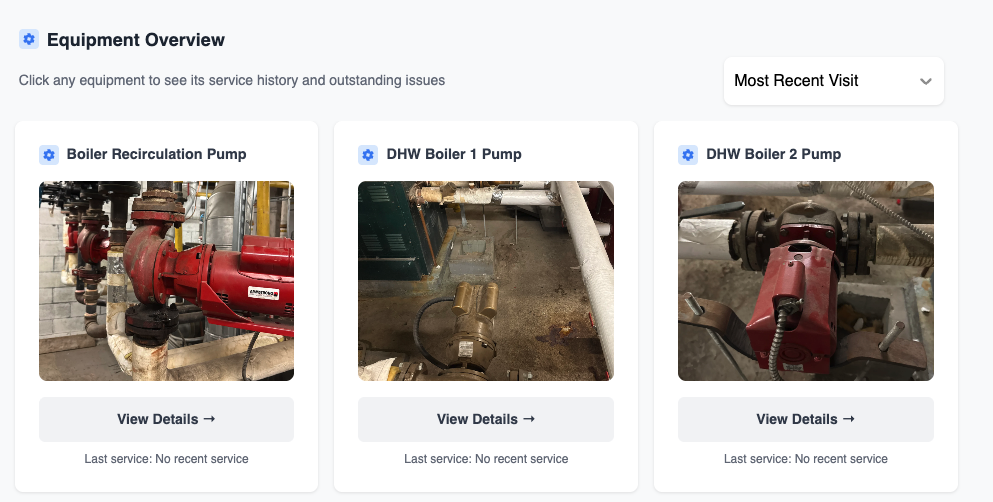

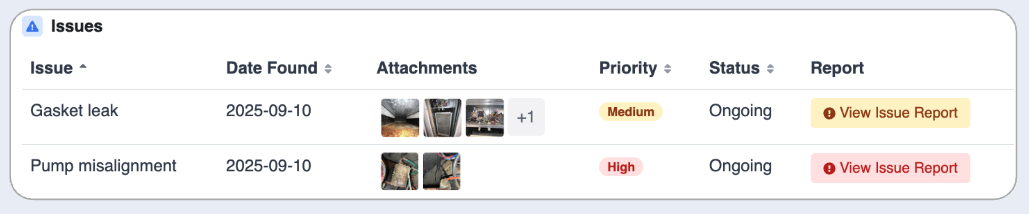

- Preventive mechanical maintenance for ongoing equipment care

- Chiller retrofit for cooling plant upgrades

- Boiler replacement for heating plant upgrades

- Cooling tower replacement for heat rejection upgrades

- Recent projects to see our completed work

FAQs

Ready to reduce your energy costs?

Request a VFD assessment to identify your highest-ROI opportunities. We'll analyze your equipment, calculate potential savings, and provide a detailed proposal including available rebates.