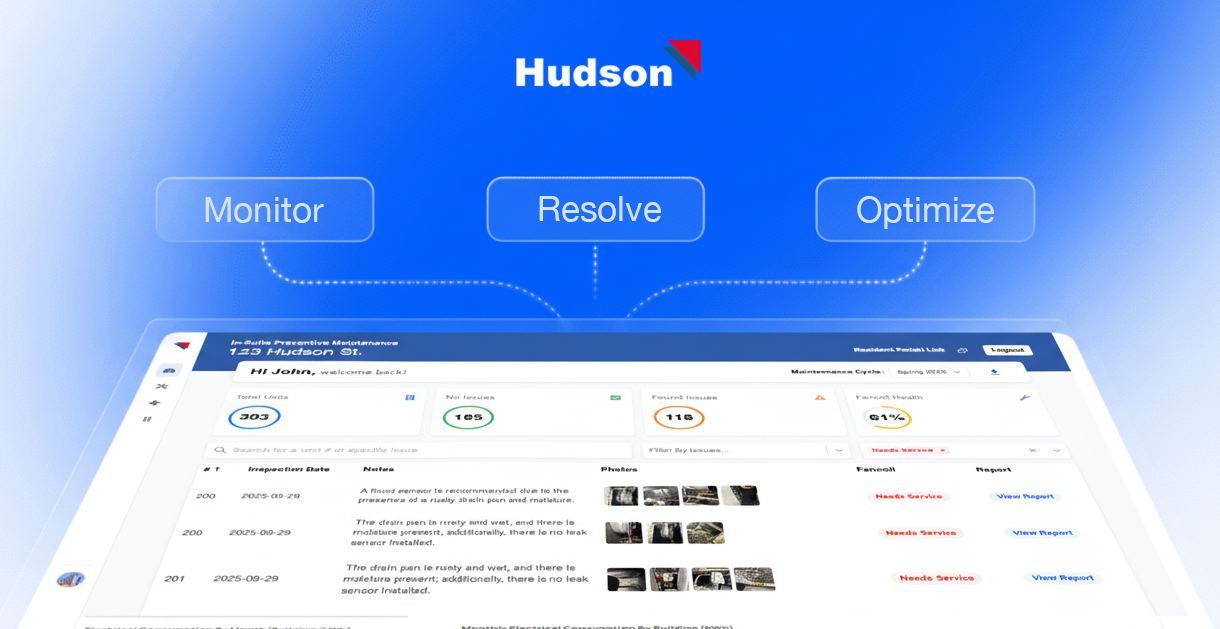

Boiler Replacement: Reliable Building Heat

Boilers are the heart of your building's heating system. When they age beyond reliable operation, replacement isn't just about comfort—it's about safety, efficiency, and avoiding mid-winter emergencies.

We manage complete boiler replacement projects from equipment selection through commissioning. Whether you're upgrading a single atmospheric boiler to high-efficiency condensing technology or replacing an entire multi-boiler plant, our team ensures minimal downtime and optimal performance.

Request Project Quote View Recent ProjectsEnergy savings

Modern condensing boilers achieve 90-98% efficiency versus 75-85% for older units. This translates to 15-25% lower natural gas bills—savings of $10,000-50,000+ annually for typical condos.

Improved reliability

New boilers with modern controls, redundant components, and proper sizing eliminate the mid-winter breakdowns that put residents at risk and require emergency repairs.

Lower emissions

High-efficiency boilers produce significantly less CO2 and NOx emissions. Many municipalities offer incentives for low-emission equipment to support climate goals.

Types of boilers we install

Different buildings have different heating requirements. We work with all common boiler configurations and can recommend the best approach for your building's needs.

Condensing Boilers

90-98% efficiency by recovering heat from flue gases. The modern standard for new installations.

Modular Systems

Multiple smaller boilers that stage on/off based on demand. Excellent redundancy and efficiency.

Fire-Tube

Traditional design with proven reliability. Good for larger capacity requirements.

Water-Tube

Compact design with quick response. Common in space-constrained mechanical rooms.

Cast Iron Sectional

Individual sections can be replaced. Good longevity but lower efficiency than condensing.

Combination Systems

Heating and domestic hot water from one system. Efficient for smaller buildings.

Why proactive boiler replacement?

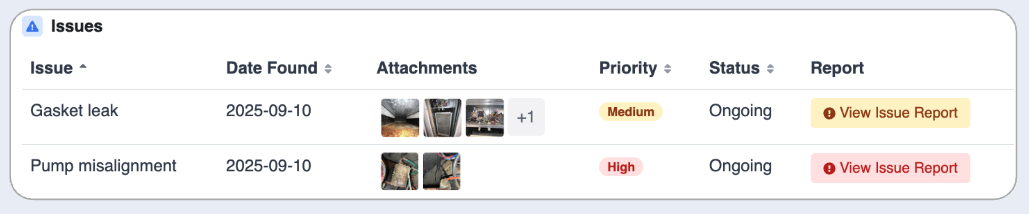

A boiler failure in January is a building emergency. Proactive replacement on your schedule is far better than reactive replacement on the boiler's schedule.

- Avoid emergencies: Old boilers fail without warning, often during cold snaps when they're working hardest. Emergency replacement costs 30-50% more and may leave residents cold for days.

- Efficiency gains: Replacing a 30-year-old atmospheric boiler with modern condensing technology can cut gas consumption by 20-30%. At current gas prices, payback is often 5-8 years.

- Parts availability: Parts for old boilers become scarce and expensive. Eventually, even routine repairs become impossible as components are discontinued.

- Insurance requirements: Insurers increasingly require documentation of boiler age and condition. Old, poorly maintained equipment can affect coverage and premiums.

Our replacement process

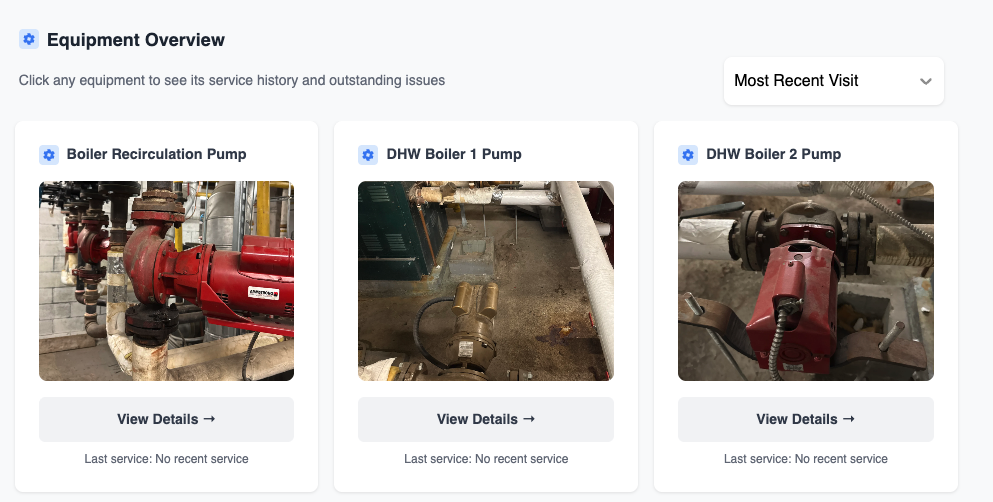

Boiler replacement requires careful planning to maintain heat during the project and ensure proper integration with existing systems.

Assessment

- Existing equipment evaluation

- Heating load calculation

- Mechanical room assessment

- Gas supply verification

- Venting requirements

Engineering

- Equipment selection

- Piping design

- Controls integration

- Venting design

- Permit applications

Procurement

- Equipment ordering

- Lead time management

- Rigging coordination

- Utility rebate applications

- Material staging

Demolition

- System isolation

- Piping disconnection

- Old boiler removal

- Asbestos abatement (if needed)

- Area preparation

Installation

- Boiler placement

- Piping connections

- Gas hookup

- Venting installation

- Controls wiring

Commissioning

- System startup

- Combustion analysis

- Safety testing

- BAS integration

- Documentation

Boiler manufacturers we install

We work with leading commercial boiler manufacturers and can recommend the best fit for your building's requirements and budget.

Aerco

High-efficiency condensing

Lochinvar

Condensing & modular

Viessmann

German engineering

Weil-McLain

Cast iron & condensing

Cleaver-Brooks

Commercial fire-tube

Fulton

Vertical water-tube

Patterson-Kelley

MACH condensing

IBC

Modular systems

Compliance & safety

Boiler replacement involves gas work, which is heavily regulated for safety. We handle all compliance requirements so you can focus on building operations.

TSSA Certification

All work performed by TSSA-licensed gas technicians (G1/G2). Proper permits obtained, inspections scheduled, and compliance certificates provided for your records.

Gas Code Compliance

All installations meet current Ontario gas code requirements including proper venting, combustion air, and safety devices. Documentation provided for insurance purposes.

Asbestos Handling

Older boilers often have asbestos insulation. We coordinate proper testing and, if needed, licensed abatement before removal. Full documentation for your building records.

For property managers & boards

Boiler replacement is a significant capital project that directly affects resident comfort and building safety. We understand the importance of proper planning, transparent communication, and reliable execution.

- Board presentations: We present options clearly, explaining trade-offs between equipment types, efficiency levels, and costs. We're available for AGMs and board meetings.

- Reserve fund alignment: Projects can be timed to match funding availability, with documentation supporting reserve fund study updates.

- Utility rebates: High-efficiency boilers often qualify for significant utility incentives. We identify and apply for applicable programs to offset project costs.

- No-heat contingency: For buildings with limited redundancy, we have contingency plans including temporary heating to ensure resident safety during the project.

Boiler Projects Across Toronto

We've completed boiler replacements in buildings across the GTA—from single-boiler mid-rises to multi-boiler high-rise plants. See our project portfolio for examples.

Related project solutions

- Preventive mechanical maintenance for ongoing boiler care

- Chiller retrofit for cooling plant upgrades

- MAU replacement for ventilation upgrades

- Riser replacement for heating distribution upgrades

- Recent projects to see our completed work

FAQs

Ready to upgrade your heating plant?

Request a site assessment and detailed proposal. We'll help you understand your options, timeline, and budget requirements for a successful boiler replacement.